- WG12. Georesources, extraction and processing

Coordination: Aurora Futuro, FEUP

Co-coordination: Teresa Carvalho, IST

Institutions: FEUP, IST, LNEG

- LA7. Integrated services for georesources

Coordination: António Fiúza, FEUP

Institutions: FEUP, IST

Working group oriented towards the availability of products and equipment in the areas of inventory, estimation, extraction and processing of mineral georesources and also in the storage and reuse of (rejected) waste.

Line fo action that aims to integrate methodologies and carry out applied studies that focus on all or any of the components of the geo-resources life cycle including open pit and/or underground mining, bio-hydrometallurgical processing of ores, physical or chemical processing of ores, environmental impacts resulting from exploration and their minimization, storage and reuse of (rejected) mining waste, life cycle analysis of specific georesources and economic pre-feasibility of exploiting geo-resources, framed by a holistic vision centered on circular economy.

+ DATA & PRODUCTS

- Maps of portuguese mineral occurences [here]

Scales 1:250 k and 1:500 k

- Database of portuguese mineral ores [here]

Nationwide information system that contains geoscientific, technical and economic information related to occurrences, resources and mineral reserves and areas with mining potential.

- Occurrence information system and portuguese mineral resources [here]

- Map of critical raw materials for mainland Portugal [here]

Compilation of known mineral deposits and occurrences, which contain some of the critical raw materials, according to the latest list published by the European Commission in September 2020.

- (available soon)

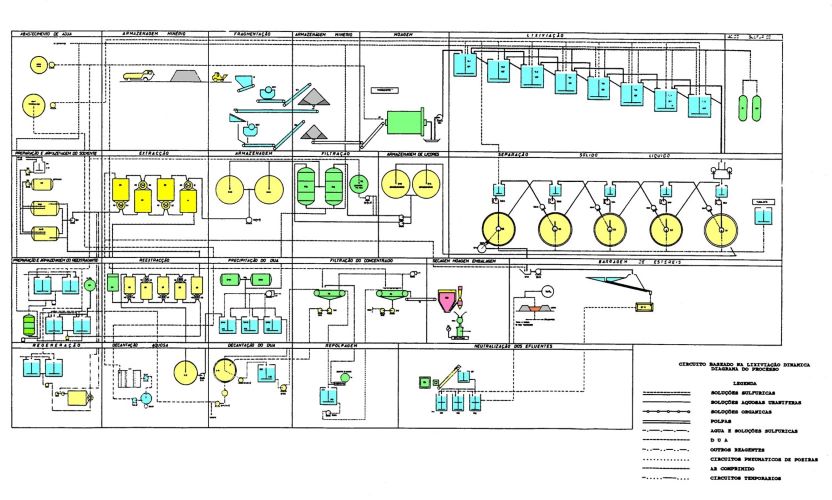

- Sequential logical flowchart for integrated or partial simulation of unit operations in the extraction and processing of ore.

More sources of mineral georesources data: EGDI, EO4RM.

+ SERVICES

| GEORESOURCES |

- 3D modeling

Geo-referenced three-dimensional modeling related to the spatial distribution of resources with the objective of their exploration.

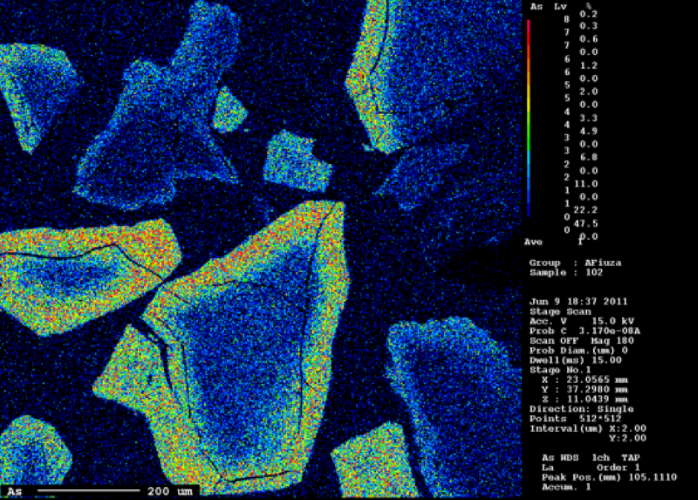

- Physical, chemical and environmental characterization of ore materials

Determination of parameters such as grain size distributions, densities, chemical compositions acid generation capacities.

- Quantitative estimation of ore reserves

Conception and selection.

- Definition of mining extraction methods

Considers the geometry of the deposit (size, shape, layout, depth and tectonics).

| EXTRACTION |

- Sizing of unit operations equipment for resource extraction

Selection, sizing and determination of the number of units of the main equipment necessary for all the unit operations involved in mining and/or quarry extraction.

- Selection of extraction equipment

Optimized integration of unit operations in the total or partial production cycle.

- Optimization of planning and operating sequences

Time optimization of the mining extraction sequences considering economic objectives and exploitation constraints.

- Estimation of mineral resources, dilution, need of ‘blending‘

Estimation of geologic resources (volume and grade), in-situ mining resources, ore dilution during extraction and need of blending.

| PROCESSING |

- Discontinuous tests of concentration and purification

Definition and/or performance of discontinuous tests of concentration and purification, of physical, chemical or biological nature in equipped laboratories.

- Preliminary proposals of Flowsheeting

Considering the composition and mineralogical associations existing in the ore.

- Development of Flowsheeting diagrams

Quantitative simulation of processing diagrams and mass balances.

- Defining criteria for equipment

Definition and laboratory determination of criteria for sizing main and auxiliary equipment

- Analysis and definition of control and automation strategies

Definition of the strategies for controlling a mineral processing plant: local strategies for each relevant unit operation (feedback, feedforward and feedback corrected by feedforward) and general strategies such as on-line optimal research and/or evolutionary operation.

- Access to software and methodological proceedings

For the characterization, dimensioning, definition and optimization of the modus operendi of specific unit operations (blasting, charge, transport, etc.)

| SPECIFIC STUDIES |

- Specific studies on georesources’ inventory and classification

Estimation of identified resources using exploration and drilling data: demonstrated and inferred (economical, marginal and sub-economic), hypothetical and speculative.

- Specific studies on georesources’ extraction area

Includes optimization of a fire diagram, definition and articulation between unit operations, optimization of dismantling, definition of types of ore considering its processing.

- Specific studies on the physical processing of ores

Includes granulometric composition and barities, definition of release, gravimetric or flotation separation tests.

- Specific studies on the minimization of the environmental impact

Includes the determination of the potential for acid drainage, biological activity in the ore, composite solutions for tailings storage, passive and active effluent treatment systems.

- Specific studies on hydrometallurgical processing

Includes tests of atmospheric and/or pressure leaching, concentration and purification of leachate and production of a solid marketable product.

- Specific studies on bio-hydrometallurgical processing

Includes aptitude for bio leaching, optimization of procedures including eventual inoculation, discontinuous and bio-reactor bio-leaching tests.

- Specific studies on decommissioning, closure and rehabilitation plans

Includes staging of a closure plan, post-operational rehabilitation, monitoring and deactivation. Study of possible new uses for the site.

- Studies of life cycle analysis of specific geo-resources

Definition of phases and boundaries: acquisition of raw materials, manufacture that includes analysis of extraction, processing and treatment and/or storage of waste, energy inventory and fugitive emissions, quantification of results: global warming potential, potential abiotic depletion, acidification potential, eutrophication potential, aquatic exo-toxicity potential in fresh water, human toxicity potential, photo-chemical and terrestrial eco-toxicity potential.

- Economic pre-feasibility studies for the exploitation of georesources

Investment and cost estimates. Exploration results. Profitability indicators. Sensitivity Analysis. Risk analysis.

- Studies on recycling of mining waste

Includes the physical, chemical and environmental characterization of rubble and/or waste, definition of recycling alternatives, inerting solutions.

- Studies on geo-environment and circular economy

Quantitative and qualitative prediction of potential environmental impacts. Circular economy: inventory and use of co-products, by-products and waste, solutions to minimize the environmental impact caused by solid effluent waste, water supply and recycling circuits; geo-environmental monitoring.

- (available soon)

- Dissemination of technological innovations in ore extraction and processing

- Technological advice on extraction and mineral processing

- Prior definition of specific technologies adapted to each type of mineral resource

- Use of equipment in extraction and mineral processing

- Laboratory techniques in extraction and mineral processing

+ TRAINING

- Training in proceedings on the use of specific equipment used in georesources

- Training in normalized protocols in the characterization of georesources

- Training on operational units of mining extraction, processing of ores, storage of rejected materials

- (available soon)

- Intensive training courses in extraction and mineral processing

Check more TRAINING available via C4G.

+ EQUIPMENT

The following equipment is used for various services in georesources and is available for sharing under conditions.

- Atomic absorption spectrometer

- Double-beam spectrophotometer

- Energy dispersive X-ray fluorescence spectrometer

- Pressure leach reactor

- Radionuclide identifier with germanium detector

- Laser diffraction particle analyzer

- Gas chromatograph for columns with FID and TCD packaging

- Gas chromatograph with capillary columns for FID and ECD

- Flotation cell

- Climatic corrosion chamber

Check more EQUIPMENT available via C4G.